-

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

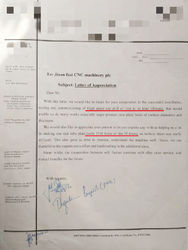

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Jinan FAST CNC High-Speed Drilling And Marking Process Line For Angles Model HSAD2532

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Материал | Углы | Функция | Бурение и маркировка |

|---|---|---|---|

| Скорость | Высокоскоростной | Размер угла (мм) | 100x100x10~250x250x32 |

| Максимум длина бланка (м) | 14 | Маркировка сила (кН) | 1000 |

| Тип маркировки | Закрытого типа | Размер символа (мм) | 14*10*20 |

| Макс. Скорость подачи (м/мин) | 4 | Шпиндельный конус | BT40 |

| Общее измерение (M) | Около 31x7x2,9 |

Jinan FAST CNC High-Speed Drilling And Marking Process Line For Angles Model JX2532

![]()

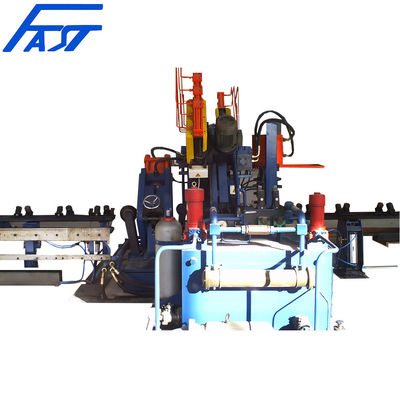

APPLICATION

This machine is used for drilling and marking large-size iron towers and high-strength angle steel in transmission lines. All the holes on the angle steel can be drilled in one pass, and the hole quality and position accuracy are high. It is a special machine for fully automated production.

FEATURES

- Integrated machine with mechanical, electrical and hydraulic elements;

- There is a drilling power head on each of the two wings of the angle steel. Each power head has a tool magazine. The tool magazine is equipped with 4 tools. The tool magazine is optional. All holes on the two wings of the angle steel can be processed in one pass;

- The drilling spindle adopts high-precision BT40 spindle;

- The drilling spindle can be used to clamp twist drills or hard alloy drills, which has a wide range of applications;

- The quasi-distance can be set arbitrarily, and the number of punching rows is not limited;

- The drilling spindle adopts BT40 precision spindle;

- The marking unit adopts a closed bed structure, which has good rigidity. Four groups of selected programming on the upper marking box. The marking distance can be set at will;

- The control system is composed of a host computer, servo motor, PLC, external detection sensor, etc.;

- The CNC feeding trolley is driven by a servo motor with high positioning accuracy;

- There are various input methods, such as keyboard and mouse input, USB interface input, network interface input.The data generated directly by the 3D or 2D software.

- The main electrical control components and hydraulic and pneumatic components are imported accessories;

- Providing G-code software program that can directly convert CAD graphics into executable machine ;

- Graph display of processed parts;

- With fault self-diagnosis function.

COMPOSITION

| Material platform | Cross feeding conveyor |

| CNC feeding trolley | CNC conveyor |

| Marking unit | Drilling unit |

| Retainer(supporting material) | Outfeeding conveyor |

| Hydraulic station | Automatic lubrication system |

| Mist cooling system | Controlling system |

TECHNICAL DATA

| Model | HSAD2532 | HSAD3635 |

| Angle Size (mm) | 100x100x10~250x250x32 | 140x140×10~360×360×35 |

| Max. Length of blank (m) | 14 | |

| Marking Force (kN) | 1000 | |

| Marking Unit Type | Closed -type | |

| Number of Marking Groups (PC) | 4 | |

| Qty. of Character in Each Character Group (Piece) | 18 | |

| Character Size (mm) | 14*10*20 | |

| Shearing Function (Optional) | ≤200 | |

| Back mark (mm) | 48~220 | 50~330 |

| Each Side Number (PC) | 1 | |

| Tool Magazine On Each Side Number (PC) | 1 | |

| Number of Tools In Each Magazine (Optional) | 4-6 | |

| Max. Feeding speed(m/min) | 40 | |

| Spindle Tapper | BT40 | |

| Max. Speed Of Drilling Spindle(r/min) | 3000 | |

| Max. Angle Infeed Speed (m/min) | 40 | |

| Max. Moving Speed Of Power Head Sliding Plate(m/min) | 10 | |

| Power Head Max. Feed Speed(m/min) | 0~5 | |

| Overall Dimension (m) | About 31x7x2.9 | About 32×7.5×3 |

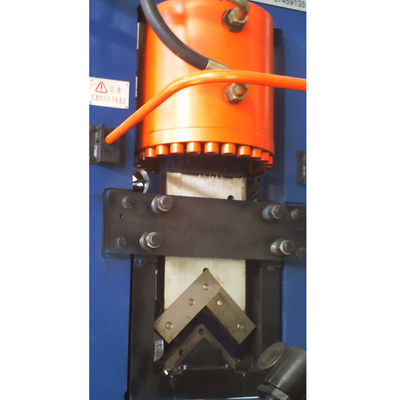

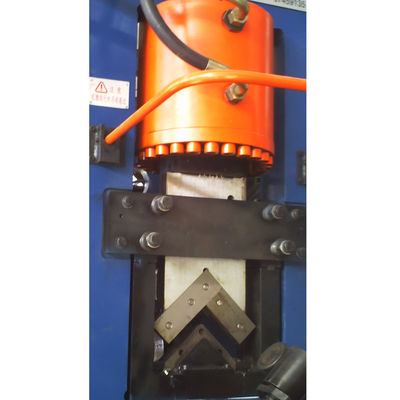

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()