-

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

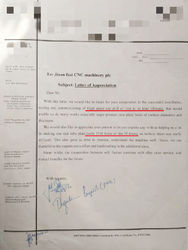

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

High Performance Economical Edgebanding With Premilling Corner Trimming Machine Imported Components Model KLF463

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | Гарантия | 12 месяцев |

|---|---|---|---|

| Порт | Циндао порт | Могил | 1 набор |

| Услуга | 24 часа онлайн -услуги | Напряжение | 380 В. |

| Сертификат | ISO9001 | ЧПУ или нет | Сжигание |

| производство | ODM OEM приемлемый | Machine Dimensions(L*W*H) | 5950*850*1550MM |

Edgebanding Machine KLF463

![]()

FEATURES

-

The gluing unit features quick melt and an application device that guarantees perfect glue quality on different edge materials.

-

Temperature adjustable by control. When the edgebander is running without workpiece, the system automatically stops heating up the glue.

-

The trimmed edge is always finished with a clean cut thanks to the precision linear guide and the high speed motors.

-

Quick changeover between different edges can be easily realized by clicking on the touchscreen.

-

4 motors that travel in a reciprocating motion to clean and buff the workpiece.

TECHNICAL DATA

| SERIES | Pre Milling | Gluing | End Trimming | Rough Trimming | Fine Trimming | Corner Trimming | Scraping | Buffing |

| KLF463 | · | · | · | · | · | · | · |

| SERIES | Machine Dimensions(L*W*H) | Power | Feed Speed | Electrics | Edge Trichness | Workpiece Thickness | Workpiece Length | Workpiece Width | Minimum Workpiece Dimension |

| KLF463 | 5950*850*1550MM | 15.7KW | 18~23m/min | 380V/50HZ/200HZ | 0.4~3mm | 12~65mm | 10~60mm | Min.120mm | Min. 80mm |

DETAILS PICTURES

![]()

Top pre-melter reduces heating time and increase the quality of edgebanding.

![]()

Servo Tape Magazine

Four wheel tape magazine automatically changes edge with servo motor.

The process is both accurate and swift.

![]()

-

One big precision roller and 5 small to make sure the edge is pressed seamlessly to the workpiece.

-

The big roller and gluing rollers press simultaneously. The 5 small rollers consist of 1 cylinder shaped and 4 cone shaped rollers. The latter further ensures that the edge is properly pressed to the workpiece.

-

All rollers have their independent pressure control valve.

R Scraping

Trimming

Corner Trimming Unit

With 4 motors, this device works well with various edge thickness and invariably result in perfect round corner.

Pre-milling Unitl

-

Equiped with diamond tools for better cut and longer use

-

This device removes the burr or unevenness on the edge of the workpiece, leaving a smooth surface for the edgebanding.

-

Profiling unit available upon request.

FAQ

· Are you a Manufacturer or a Trading company?

Manufacturer + trading company (integration),focusing on CNC machines for 18 years. Integration with Design,Machining and Assembly.

Exporting to Russia,USA,Australia,Vietnam,Brazil,Ethiopia,Tunisia,Bulgaria,India,Indonesia,Jordan,Pakistan,etc

· Do you have stock product ready to delivery?

In order to satisfy with customer for fast delivery, we have certain amount of machines in stock.

· After an order is placed,when to delivery?

General 30 working days. It depends on specific items and item quantities.

Please check with sale manager for exact delivery time.

· What is the Warranty with After-sale Services?

12 months warranty after delivery. Engineers will provide training program for operation and trouble shouting during installation. They visit customers regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

After the warranty, the professional after-sale service team will provide perfect technical support and help customer solve problems encountered.

· What about the product quality?

Each machine must be carried out quality examination and test when shipping and delivery goods.