-

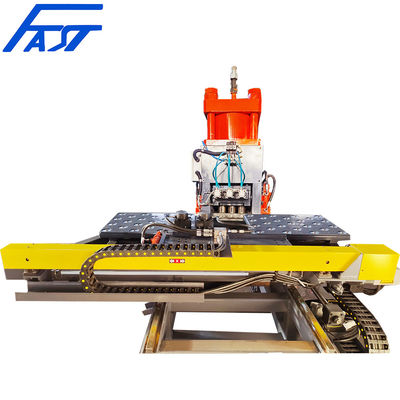

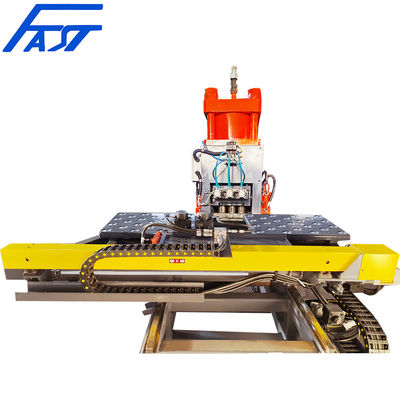

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

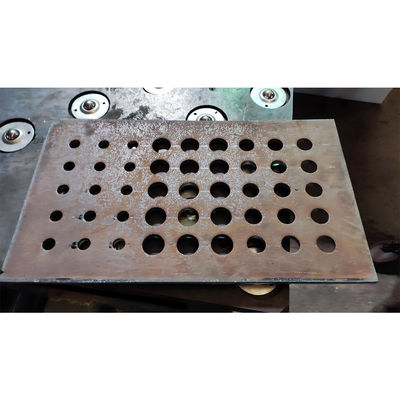

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

CJ123 Automatic Hydraulic CNC Plate Punching Machine For Tower Connecting Plate

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | Гарантия | 12 месяц |

|---|---|---|---|

| Max. Size of Work Piece L*W (mm) | 1500*800 | Max. diameter of punching (mm) | Φ40 |

| Plunging Force (KN) | 1200 | Dimensions of Characters (mm) | 14*10*20 |

| Quantity of Characters | 14/18 | Overall Dimension L*W*H (mm) | 3700*2520*1875 |

| Programming Mode | Input by keyboard, RS232 interface, floppy disk and USB interface | Precision | Accordance with GB2694-2003 |

| Name | Specification | |

|---|---|---|

| Color | Black & Yellow | |

| Controlling System Language | English (Option:Russia) |

CJ123 Automatic Hydraulic CNC Plate Punching Machine For Tower Connecting Plate Export To India

![]()

APPLICATION

This machine is used for punching and marking on connecting plates in iron tower and steel structure industries. It can also be used for punching and marking of sheet metal processing in other industries.

FEATURES

- The machine body is a C-shaped steel plate welded structure, which has good rigidity and large processing space. This machine is equipped with three mold positions (including a marking workstation. The mold position switching is performed automatically.

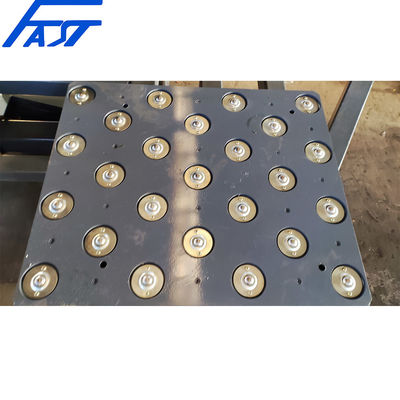

- The clamping system can adapt to different thicknesses workpieces, with a reference zero stop. The workpiece is supported by a rolling ball table.

- The operation of X-axis and Y-axis is driven by servo motor and ball screw. Dual-axis numerical control system controls punching position. The whole processing process is automatic. The operator inputs the size of the workpiece into the computer, which can be called repeatedly in the future;

- Adopting numerical control system, servo motor feeding, high efficiency, stable workpiece punching accuracy;

- The main functional components adopt modular assembly, which is convenient for maintenance;

- Easy programming, input hole size, position, number of workpieces. The operator can also use the program generated by the lofting software, or adopt CAD/CAM direct conversion, providing network port, can share data resources with technical departments to form a local area network;

- With fault self-diagnosis function;

- Punching and marking can be realized on the same board; it improves production efficiency and reduces labor intensity of workers;

- Key hydraulic, pneumatic and electrical components are imported;

- The hydraulic station adopts water cooling.

TECHNICAL DATA

| Model | CJ103 | CJ104 | CJ121 | CJ123 | |

| Max. Size of Work Piece L*W (mm) | 1500*800 | 1500*800 | 1500*800 | 1500*800 | |

| Max. diameter of punching (mm) | Φ32 | Φ32 | Φ40 | Φ40 | |

| Plate Thickness of Punching (mm) | 5~20 | 5~25 | 5~25 | 5~25 | |

| Max. diameter of Drilling | Φ50 | ||||

| Punching Force (kN) | 1000 | 1000 | 1200 | 1200 | |

| Marking Force (kN) | 1000 | 1000 | 1200 | 1200 | |

| Min. Distance Between Hole And Plate Edge (mm) | Punching | 25 | 25 |

30

|

30 |

| Drilling | Depends on hole diameter | ||||

| Dimensions of Characters (mm) | 14*10*20 | 14*10*20 | 14*10*20 | 14*10*20 | |

|

Quantity of Characters |

14/18 | 14/18 | 14/18 | 14/18 | |

| Die-Stations | 3 | 4 | 1 | 3 | |

| Feeding Speed of Drilling (mm/min) | 20~280 | ||||

| Strok of Drilling Spindle (mm) | 180 | ||||

| Rotation Speed of Drilling Spindle (r/min) | 100~750 | ||||

| Precision | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | |

| Programming Mode | Input by keyboard, RS232 interface, floppy disk and USB interface | ||||

| Overall Dimension L*W*H (mm) | 3200*2520*1875 | 3500*2520*2600 | 3700*2520*1875 | 3700*2520*1875 | |

| Model | CJ80 |

CJ161/ CJ163 |

CJ201/ CJ202/ CJ203 |

CJ301 |

| Max. Size of Work Piece L*W (mm) | 4000*1800 | 1500*800 | 1500*1500 | 1850*1850 |

| Max. diameter of punching (mm) | Depends on Workpiece Thickness | Φ50 | Φ50 | Φ60 |

| Plate Thickness of Punching (mm) | 2~10 | 5~25 | 5~30 | 5~30 |

| Punching Force (kN) | 800 | 1600 | 2000 | 3000 |

| Marking Force (kN) | 800 | None | None | None |

|

Min. Distance Between Hole And Plate Edge (mm)

|

20 | 30 | 25-35, Φ≤37mm; 35~50,37mm<Φ≤60mm | |

|

Dimensions of Characters (mm)

|

14*10*12 | None | None | None |

|

Quantity of Characters |

14 | None | None | None |

| Die-Stations |

1 ~ 7 By Customer’s Request |

1/3 | 1/2/3 | 1 |

| Precision | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 | Accordance with GB2694-2003 |

★ All of these models can be customized according to customer requirements.

DETAIL IMAGES

![]()

![]()

![]()

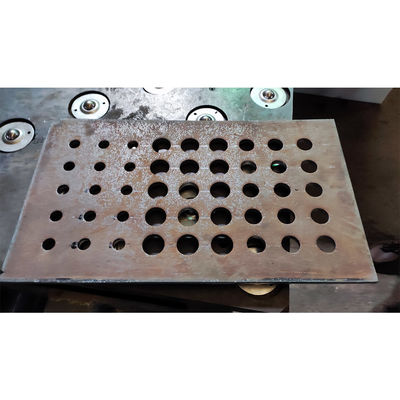

![]()

SAMPLES

![]()

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()