-

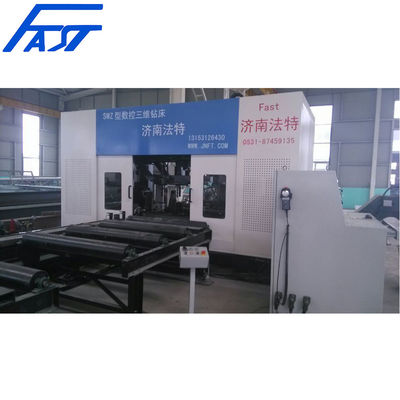

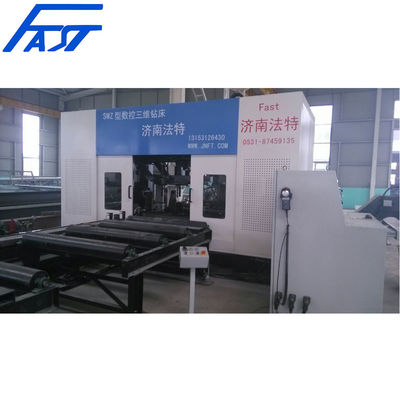

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Jinan FAST High Performace CNC High Speed H Beam Drilling Machine Production Line Model SWZ1000

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | Гарантия | 12 месяцев |

|---|---|---|---|

| Порт | Циндао порт | Могил | 1 набор |

| Услуга | 24 часа онлайн -услуги | Напряжение | 380 В. |

| Сертификат | ISO9001 | ЧПУ или нет | Сжигание |

| производство | ODM OEM приемлемый | Функция | Бурение |

Jinan FAST High Performace CNC High Speed H Beam Drilling Machine Production Line Model SWZ1000

![]()

APPLICATION

This machine is used for drilling H-beam, channel steel, box beam, angle steel and other industries in steel structure, bridge, three-dimensional parking garage, petroleum platform and other industries. It adopts high-speed spindle processing with high efficiency and high precision.

FEATURES

- Integrated machine with mechanical, electrical and hydraulic elements;

- This machine has three power heads. Each power head has a tool magazine. The tool magazine is equipped with 4 tools. The tool magazine is optional. All holes on the three sides of the workpiece can be processed in one pass;

- The drilling spindle adopts high-precision BT40 spindle;

- The drilling spindle can be used to clamp twist drills or hard alloy drills, which has a wide range of applications;

- The bed is welded by thick-walled steel pipes. The aging treatment is carried out after welding to ensure the stability of the bed and the accuracy of the entire machine tool.

- The control system is composed of a host computer, servo motor, PLC, external detection sensor, etc.;

- The CNC feeding trolley is driven by a servo motor with high positioning accuracy;

- There are positioning cylinders on the upper and lower raceways to ensure the accuracy of drilling;

- There are various input methods, such as keyboard and mouse input, USB interface input, network interface input.The data generated directly by the 3D or 2D software.

- The main electrical control components and hydraulic and pneumatic components are imported accessories;

- Providing G-code software program that can directly convert CAD graphics into executable machine ;

- Graph display of processed parts;

- With fault self-diagnosis function.

COMPOSITION

| Horizontal storage rack | Workpiece lifting and handling trolley (transferred from the material rack to the feeding side raceway) |

| CNC Infeeding Trolley | CNC trolley running track |

| Loading side power raceway | Three-dimensional drilling unit |

| Offloading side power raceway | Side pusher system |

| Automatic chip conveyor | Mist cooling system |

| Electric control cabinet | Hydraulic station |

TECHNICAL DATA

| Model | SWZG400-3 | SWZG700-3 | SWZG1000-3 | SWZG1250-3 |

| H-beam Max. Web Weight*Max. Flange Height (mm) | 400*300 | 700*400 | 1000*500 | 1250*600 |

| H-beam Min. Web Weight *Min. Flange Height (mm) | 100*75 | 150*100 | ||

| Automatic Feeding Length (mm) | 1500~12000 | 2000~~14000 | ||

| Max. Web Thickness (mm) | ≤60 | |||

| Max. Drilling Diameter (mm) | Φ40 | |||

| Feeding Speed (mm/min) | 20~5000 | |||

| NO. of Spindle | 3 | |||

| Rotation Range of Each Spindle (r/min) | 100~3000 | |||

| Spindle Type | BT40 | |||

| Tool Magazine (Optional) | 3 | |||

| Number of Tools In Tool Magazine (Optional) | 3*4 | |||

| Cooling | With Air Cooling System | |||

| Upper Spindle Movement Range (mm) | 20~360 | 40~660 | 40~960 | 40~1160 |

| Left and Right Spindle movement range (mm) | 20~280 | 30~370 | 30~470 | 30~570 |

| Marking Function(Optional) Marking Number | 36 | |||

| Character Size (mm) | 14*10*20 | |||

| Overall Dimension L*W*H (m) | 22*4*3.2 | 29*4.2*3.4 | 33*4.5*3.6 | 33*4.8*3.8 |

★ All of these models can be customized according to customer requirements.

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

![]()

SAMPLES

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()