-

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

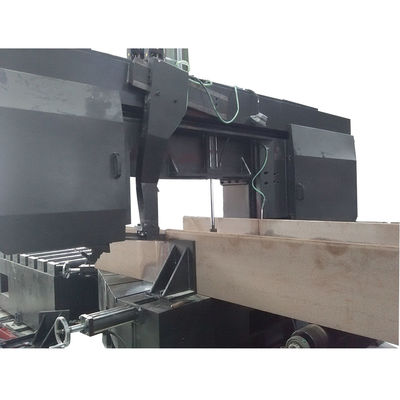

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Automatic H/I/U beam Band Sawing Machine Automatic Bandsaw Machine Metal Cutting

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | ЧПУ или нет | Сжигание |

|---|---|---|---|

| Гарантия | 12 месяцев | Напряжение | 380 В. |

| Чистый вес (кг) | 6500 | Сила гидравлического двигателя (кВт) | 4 |

| Cooling system(W) | 100 | Порт | Циндао порт |

| Минимальный заказ | 1 набор | Main Motor Power ( kW) | 7.5 |

| Name | Specification | |

|---|---|---|

| Color | Black & White | |

| Controlling System Language | English (Option:Russia) |

Automatic CNC Rotation Band Sawing Machine For H Beams Model SAW1250/SAW1050

![]()

APPLICATION

This machine is used for sawing H-beam, steel bar, round steel and other profiles.Narrow saw cutting, high cutting precision, convenient operation and high production efficiency.

This machine is used to cut all kinds of large-scale steels. The saw frame can rotate on the platform, which can meet the cutting of all kinds of steel end faces at a certain degree. The degree can be adjusted between 0-45 degrees. When the degree is 0 degrees, the maximum cutting height is 600mm, and the width is 1250mm. It can also cut all kinds of black or non-ferrous metal materials after selecting appropriate processing parameters.

FEATURES

- According to the section of the workpiece, the feed speed can be adjusted intelligently. The reciprocating sawing can be realized at the same time;

- This machine realizes high-efficiency and high-precision corner positioning;

- The automatic fixed-length feeding mechanism is optional to realize the automatic control of the whole process;

- There are two sets of hydraulic vise at the front and back. The two sets can be operated separately;

- Pre-input workpiece parameters, processing parameters, real-time data display and monitoring;

- This machine is specially designed for all kinds of section steel processing.

DESCRIPTION

1.Double column design, with high strength bed, in the high-speed sawing has a good vibration absorption performance.

2. It can rotate itself, and the longer workpiece can be inclined to cut from 0° to 45° without rotation, so as to maintain the continuity of production.

3, Saw blade drive motor power, to ensure the main transmission performance is good, specialized processing of steel structure industry of various types of steel.

4. Automatic hydraulic tension device of saw blade can keep the saw blade stable in high-speed rotation and extend the service life of the saw blade.

5. The left, middle and right three clamping arms and guide the saw blade, prevent the saw blade deviation, to overcome the phenomenon of clamping saw in high-speed cutting.

6. Saw blade produces fine sawing, high section accuracy, and greatly reduces material consumption.

7. The automatic cooling fluid works with the feed of the saw blade to optimize the lubrication of the saw blade and reduce the temperature rise of the saw blade.

8. The laser alignment function, and manual fine-tuning workpiece advance and retreat mechanism, facilitate the length cut.

9.PLC control, saw cutting speed through the main motor frequency conversion adjustable, saw cutting feed speed through hydraulic stepless speed regulation, greatly improve productivity.

10. The key mechanical, hydraulic, electrical components and components selected from well-known companies at home and abroad.

11. More features, please contact us.

COMPOSITION

| Sawing frame | Worktable |

| Vertical feeding device | Vertical pressing device |

| Rotation worktable | Carriage for feeding workpiece |

| Hydraulic system | Cooling system |

| Electric system | Carriage for feeding workpiece |

TECHNICAL DATA

| Model | SAW600 | SAW1000 | SAW1250 |

| Sawing H-beam Size (without Rotation)(mm)(Section H*W) | H-Beam: 600*400 | H-Beam: 1000*500 | H-Beam: 1250*600 |

| Square Beam: 400*400 | Square Beam: 500*500 | Square Beam: 600*600 | |

| Round Steel:Φ400 | Round Steel:Φ500 | Round Steel:Φ600 | |

| Blade Specifications | T: 1.3/W: 41/C: 6600 | T: 1.6/W: 54/C: 7600 | T: 1.6/W: 54/C: 8300 |

| Saw Blade Speed (m/min) | 20-100m/min | ||

| Worktable Height (mm) | 800 | ||

| Rotation Angle (°) | 0°~45° | ||

| Cutting feed speed | Stepless feed | ||

| Rotation Angle structure | Key control | ||

| Main Motor Power ( kW) | 5.5 | 7.5 | |

| Motor power of turntable ( W) | 40 | ||

| Cooling system(W) | 100 | ||

| Hydraulic Motor Power (kW) | 4 | ||

| Net Weight (kg) | 5000 | 6000 | 6500 |

★ All of these models can be customized according to customer requirements.

DETAIL IMAGES

![]()

![]()

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()