-

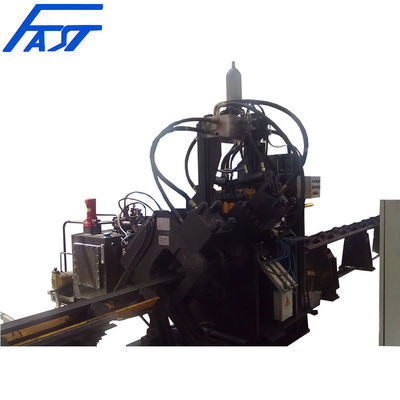

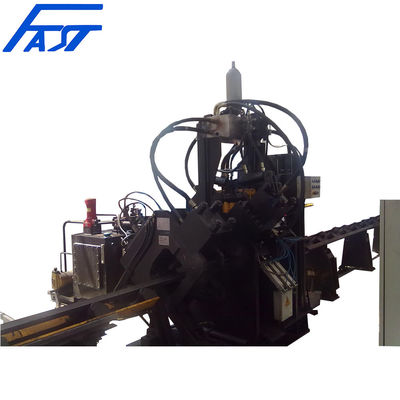

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

APM1616 CNC High Precision Angle Punching Marking And Cutting Machine Angle Production Line Angle Tower Transmission Lin

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | Гарантия | 12 месяцев |

|---|---|---|---|

| Порт | Циндао порт | Могил | 1 набор |

| Услуга | 24 часа онлайн -услуги | Напряжение | 380 В. |

| Сертификат | ISO9001 | Масса | 15000 кг |

| Overall Dimension (m) | About 23*7*2.4 | Function | marking, punching, and shearing |

| Name | Specification | |

|---|---|---|

| Color | Black & White | |

| Controlling System Language | English (Option: Russia) |

APM1616 FASTCNC Angle Iron Shearing Marking Punching Machine For Power Transmission Tower

![]()

APPLICATION

This machine is mainly used for angle steel marking, punching, and shearing special machine for fully automated production. It is widely used in power towers, communication towers, three-dimensional garages, steel structure buildings and other industries.

FEATURES

- Integrated machine with mechanical, electrical and hydraulic elements;

- There are three sets of punching dies on the two wings of the angle steel. All the holes on the angle steel can be processed in one pass;

- Single-edged cutting saves raw materials and cuts the surface neatly;

- The quasi-distance can be set arbitrarily, and the number of punching rows is not limited;

- The marking unit adopts a closed bed structure, which has good rigidity. Four groups of selected programming on the upper marking box. The marking distance can be set at will;

- The hydraulic system mainly completes punching, cutting, marking, pressing and marking box interchanging;

- The control system is composed of a host computer, servo motor, PLC, external detection sensor, etc.;

- The CNC feeding trolley is driven by a servo motor with high positioning accuracy. The structure adopts a linear guide rail and hard racks, which has a long life and a more stable performance;

- There are various input methods, such as keyboard and mouse input, USB interface input, network interface input.The data generated directly by the 3D or 2D software.

- The main electrical control components and hydraulic and pneumatic components are imported accessories;

- Providing G-code software program that can directly convert CAD graphics into executable machine ;

- Graph display of processed parts;

- With fault self-diagnosis function.

COMPOSITION

| Material platform | Cross feeding conveyor |

| CNC feeding trolley | CNC conveyor |

| CNC marking unit | CNC punching unit |

| Retainer(supporting material) | CNC cutting unit |

| Outfeeding conveyor | Hydraulic station |

| Controlling system |

TECHNICAL DATA

| Model | JX1412 | JX1412-2 | JX1412-3 |

| Function | Punching, Marking,Shearing | ||

| Angle Size (mm) | 40*40*3~140*140*12 | 40*40*3~140*140*12 | 40*40*3~140*140*12 |

| Max. Punching (D*T) (mm) |

Φ26x12

|

Φ26x12 | Φ26x12 |

| Punching Force (kN) | 630 | 1000 | 1000 |

| Marking Force (kN) | 700 | 1000 | 1000 |

| Shearing Force (kN) | 900 | 1600 | 1600 |

| Max. Length of blank(m) | 12 | 12 | 12 |

| Max.length of finished (m) | 8 | 8 | 8 |

| Qty. Of punching head on each side (pcs) | 2 | 2 | 3 |

| NO. of Character Group (Piece) | 4 | 4 | 4 |

| Character Size (mm) | 14*10*20 | ||

| Shearing modes | Double blade | Single blade | |

| CNC Axes (Piece) | 3 | ||

| Feeding Speed of Angle (m/mm) | 80 | ||

| Programming Mode | Lofting software or instruction programming | ||

| Overall Dimension (m) | About 23*7*2.4 | About 23*7*2.4 | About 23*7*2.4 |

| Net Weight (kg) | About 15000 | About 16000 | About 16500 |

★ All of these models can be customized according to customer requirements.

DETAIL IMAGES

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()