-

Станок для высокоскоростного сверления с ЧПУ

-

машина cnc сверля

-

Гидравлический штамповочно-маркировочный станок с ЧПУ для листового металла

-

Ленточнопильный станок

-

Линия сверления балок

-

Линия пробивки/сверления/маркировки/резки для уголка с ЧПУ

-

Линия обработки плоского проката/швеллера с ЧПУ

-

выправлять машину

-

Лазерная машина с ЧПУ

-

Оптовая продажа экранных пластин

-

отмечать машина

-

надрезать машину

-

станок с ЧПУ для деревообработки

-

Другой станок с ЧПУ

-

Тестирование машина

-

Аксессуар

-

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Г-н БегаллКому: Jinan FAST CNC Machinery PLC Уважаемый господин, Настоящим письмом мы хотели бы поблагодарить вас за сотрудничество в успешной установке, тестировании и вводе в эксплуатацию высокоскоростного сверлильного станка с ЧПУ, первого в своем роде в Эфиопии, который позволит нам выполнять множество работ, особенно сверление отверстий в трубных решетках для сахарной продукции различных диаметров и толщин. ... С уважением

Jinan FAST CNC Drilling Machine For Plate Model PM5050N/2

Свяжитесь со мной для бесплатных образцов и купонов.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас возникнут вопросы, мы предоставляем круглосуточную онлайн-поддержку.

x| Состояние | Новый | Гарантия | 12 месяцев |

|---|---|---|---|

| Напряжение | 380 В. | Служба послепродажи предоставлена | Инженеры доступны для обслуживания машины за рубежом |

| ЧПУ или нет | Сжигание | Тип | Сверлильный станок |

| Max.Hole Distance L×W (mm) | 6000*6000 | Макс. Толщина (мм) | 250 |

| Максимальный диаметр бурения (мм) | Φ80 | Main Axes Taper Hole | BT50 |

| Name | Specification | |

|---|---|---|

| Color | Black & White | |

| Controlling System Language | English (Option: Russia) |

CNC Drilling Machine for Plate Model PM5050N/2

![]()

APPLICATION

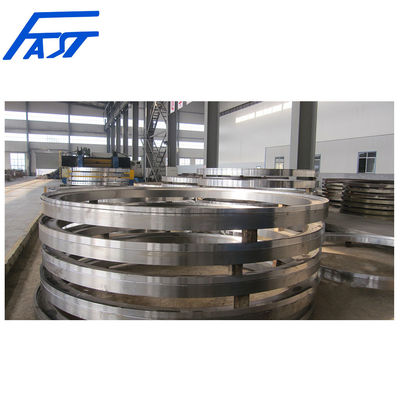

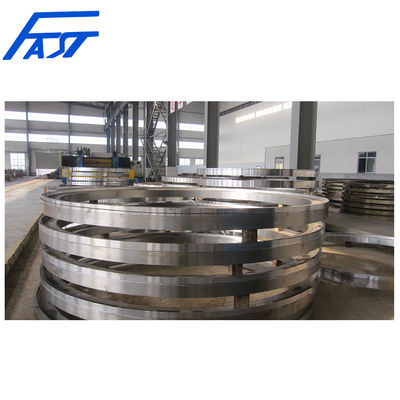

This machine is mainly used for drilling flanges, tube sheets, baffles and gear rings in petrochemical, boiler, wind power, engineering machinery.etc. It can process through holes and blind holes on single material parts and composite materials. It can also mill pipe holes and expand pipe grooves (using special tools).Also, it can be used for drilling plates in steel structure industries such as construction, bridges, and iron towers. It can realize automation, high precision, multiple varieties and mass production.

FEATURES

1. This machine is fully digitally controlled. CNC system controls servo automatically position and feed to ensure the accuracy of the drilling position;

2. The movable gantry is installed on the left and right rail seats, with good dynamic and static rigidity. Worktable is stationary;

3. This machine adopts numerical control ram type drilling and milling power head, which has high drilling precision, high efficiency, convenient use and simple maintenance;

4. It has the functions of light milling, drilling, tapping and chamfering.

5. There are a number of T-shaped grooves on the workbench, which are used to clamp fixtures and workpieces.

6. Hydraulic clamping locks, not shaking when the power head and gantry drilling;

7. Equipped with a tool magazine, it is extremely convenient to load and unload tools.

8. Linear guide line and ball screw fully protected and not exposed;

9. Flat chain automatic chip conveyor & Circulating cooling device;

10. Automatic lubrication device & Protection device. All moving (rotating) parts are automatically lubricated regularly;

11. Gantry beams & columns are widened and all steel plate welded, which is with good rigidity.

12. Full digital numerical control system control:

-Chip breaking function; Tool lifting chip removal function;

-Automatically converting CAD graphics into processing programs function;

- Adjusting the feed and speed according to different apertures,

-The standard numerical control system adopts the German Siemens numerical control system. It is equipped with a USB interface and an LCD liquid crystal display. The operation interface has functions such as human-machine dialogue, error compensation, and automatic alarm.

-Hole position preview and re-inspection function.

COMPOSITION

| Worktable | Movable Gantry |

| Drilling Power Head | Automatic Chip Conveyor |

| Circulating Cooling Device | Automatic Lubrication |

| Hydraulic System | Pneumatic System |

| Electrical System |

TECHNICAL DATA

| Model | PZ2020G | PZ3030G | PZ4040G | PZ5050G | PZ6060G | |

| Max. Size of Work piece(mm) | Max.Hole Distance L×W (mm) | 2000*2000 | 3000*3000 | 4000*4000 | 5000*5000 | 6000*6000 |

| Max. Thickness (mm) | 250 | 250 | 250 | 250 | 250 | |

|

The Distance Between The Lower Part of The Axes and the Work Bench(mm) |

230~730 | |||||

| Milling | Φ100 Cutter Head, Depth 2mm (Material Q345) | |||||

| Max. Drilling Diameter (mm) | Φ50 | Φ50 | Φ50 | Φ50 | Φ80 | |

| Drilling power head Quantity | 1 | 1 OR 2 | 2 | 2 | 2 | |

| Main Axes Taper Hole | BT50 | |||||

| Rotating Speed of Drilling Spindle (r/min) | 30~2500 | 30~2500 | 30~2500 | 30~2500 | 30~2500 | |

| Motor Power of Drilling Spindle (kW) | 22 | 22 OR 22*2 |

22*2 | 22*2 | 22*2 | |

| Longitudinal Movement(X-axis) Max Stroke (mm) | 2000 | 3000 | 4000 | 5000 | 6000 | |

| X-axis Movement Speed (m/min) | 0~8000 | |||||

| Lateral Movement(Y axis) Max. Distance (mm) | 2000 | 3000 | 4000 | 5000 | 6000 | |

| Y-axis Movement Speed (m/min) | 0~8000 | |||||

| Vertical Max. Stroke of Z-axis | 500 | 500 | 500 | 500 | 500 | |

| Feeding Speed of Z axis | 0~4000 | |||||

| Positioning accuracy | ≤0.04 | |||||

| Repeat positioning accuracy | ≤0.03 | |||||

| Number of clip cleaner | 2 | |||||

| Speed of Clip Removal (m/min) | 1 | |||||

| Clip Removal Motor Power(kW) | 20.75 | |||||

| Outline Dimension L*W*H(mm) | 4600*4200*3900 | 5800*5520*3900 | 7600*6540*3900 | 9200*8500*4300 | 9680*.9520*6000 | |

| Machine Weight(T) | 24 | 35 | 56 | 70 | 75 | |

DETAIL IMAGES

![]()

![]()

![]()

![]()

SAMPLES

![]()

![]()

![]()

![]()

![]()

WHY CHOOSE US

![]()

COMPANY PROFILE

![]()

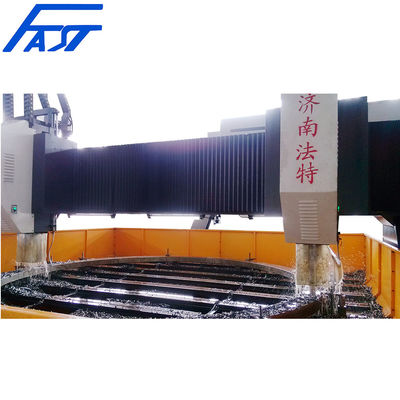

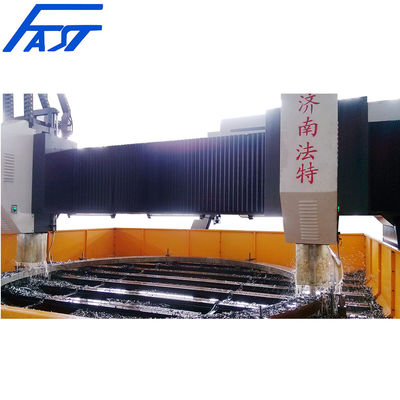

WORKSHOP

![]()

CUSTOMER VISIT

![]()

FAQ

![]()

CERTIFICATE

![]()

PACKING AND SHIPPING

![]()